My Cheesemaking Travels, Isle of Mull 2014 2/3

This week has been pretty good. I’m beginning to settle into a routine and enjoy that sense of getting more established somewhere. I head in to the creamery for about 6.30am every morning, work till around half 1 and then go home for lunch. Then it’s back for afternoon milking from 3.30pm till about half 6. It’s a reasonably full day which feels good and although I then tend to just go home, make supper and sleep I quite like the rhythm of it all. There have also been a few evenings at the pub so I’m getting a chance to let my hair down too in case you’re worrying this all sounds a bit serious and worthy.

The Creamery

The cheese is made in a large, high ceilinged room. Half of one side is filled by the long milk vat (holds 5000 litres) which sits at a raised level around head height and pours into the cheese vat (holds around 3000 litres). This produces 18 of the 25 kilo truckles that the farm is known for at least four days every week. The rest of the room houses the blue vat (holds about 1200 litres), a separate blue ageing room plus ‘hastening’ box and a range of tables, sinks, presses and a larding station.

Milking is finished by around 7am every day. The milk tanks sit between the parlour and creamery so the milk can go straight into the vat as soon as it’s ready. They have two tanks and use a mixture of the previous day and that day’s milk for each cheese make. The milk vat is continually stirred and starter culture and rennet are added. They use animal rennet for the ‘cheddar’ and vegetable rennet for the blue. They can afford the longer time the rennet takes to set for the blue as it’s a smaller volume of milk and made less regularly. The curds in the large vat are then cut and heated to around 40 degrees. They go from beautiful silky slippery things to small dry raisin like bundles that cluster together.

Once ‘pitched’ into the smaller cheese vat at ground level all of the whey is drained off which means the curd will settle into one huge, solid mass unless constantly stirred. The modern ‘industrial’ method is to have paddles continually move the curds until the lactic acid is at 5 TA (titratable acidity). Traditional practices require the curd to be cut in rectangles and placed on top of one another continually along the sides of the vat to extract the whey; a process called ‘cheddaring’ until the same acid level is reached. I’ve seen and taken part in both methods here and have sympathy with the modern method which in honesty seems much simpler, quicker and easier. Apparently there is no difference in taste.

Once our magic acid measure has been reached it is milling time with all the curd salted and passed through the mill to end up as ripped shreds which are very tasty especially when you’ve been working for hours. Imagine torn up small pieces of bread that you might dip into olive oil and that’s about the right size and shape. The milled curd is stirred some more until its temperature falls to 30 degrees and is shovelled into the 18 large moulds for pressing. The whole process can take between 5 and 7 hours and has moments of frenetic activity followed by rather a lot of standing around that I tend to get a bit impatient with. Pete (the cheesemaker) says I should learn to stand still and not need to do something all the time, he probably has a point.

The Milking Parlour

This parlour is a distinct improvement on my experience of milking in America last summer. We get to stand up rather than crouching down in the dirt and it is light and relatively airy which is wonderful. There is room for 14 cows either side (though I did accidentally manage to fit 17 at one point much to the cowman’s disbelief – he blamed me for making them shit everywhere more than usual because they were so squeezed in which I childishly found hilarious) and there are 14 clusters which alternate between the two sides. You stand below them in a pit which is narrow but has enough room for two people to move up and down; with a bit of inevitable crashing into clusters and hoses on my part.

First the cows are stripped (milking each teat to make sure there’s no mastitis or anything else of concern), then they are foamed with an antiseptic foam, then wiped thoroughly with paper towels and then hooked up to the cluster. Once they’ve been milked they are dipped and then sent back out. These basic principles of milking seem the same everywhere but it would be interesting to know if anyone does it differently.

I really like milking. It’s odd because there’s plenty not to like; constant risk of being splattered in cow shit or urine, getting covered in both at some point or another (although I have never suffered a direct hit – hurrah!), strong smells that most people would find off putting, the cows that don’t like being milked kicking and shoving, swearing cowmen getting cross with the difficult beasts etc. And yet, I do love it. The cows are cosy and curious as they buffet you in the rush to either get into or away from the parlour (usually the opposite of whatever you want them to do) their teats are warm and often amazingly soft as you set them up for milking and the smells are reassuring and real somehow. There is a sense of rightness to it all, a natural rhythm.

I am beginning to bear the scars of my labour. This is pleasing to me because I see it as evidence that I am working hard. Being kicked and shoved a bit by the cows, left scalded and aching by the creamery all seem fitting somehow as do my interesting array of rashes that I assume must be a reaction to a cleaning product of some kind. Goodness knows which one. Cheesemaking is a cleaning game as you all know by now. It’s amazing how little actual cheesemaking goes on amongst the never ending business of preparing and clearing up. Sometimes I worry I’m spending my annual leave just cleaning not furthering my understanding of cheesemaking at all.

High Point

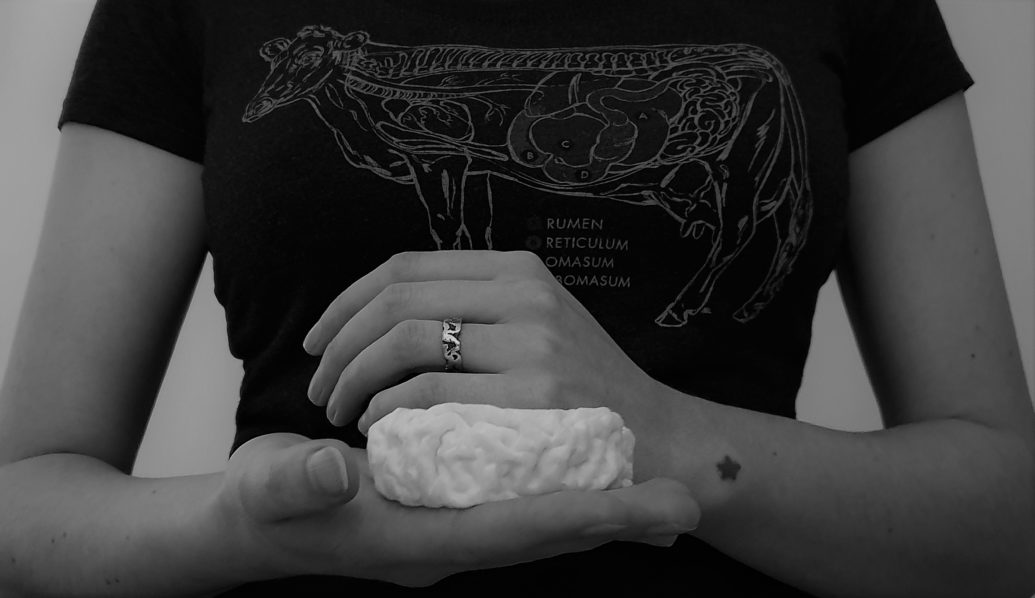

Making soft cream cheese from a churn! Really chuffed about this. To make soft cheese from scratch over the course of three days by hand is really satisfying. It’s something I could do at home and as soon as I track down a decent churn I actually think I might give it a go. Soft cheese isn’t technically ‘proper’ cheese but it’s something and I’ve got to start somewhere.

Low Point

Discovering the nature of living in such a small place. You go for a couple of drinks with one herdsman from the farm and never hear the last of it. Seriously, I am not used to everyone knowing my business and not keen on it at all.

* Names have been changed.